1/2

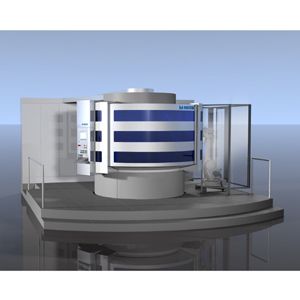

MIKRON NRG-50

Mikron Machining Technology stands for technological innovation, extreme precision with large quantities and high flexibility. The machining of parts is carried out on unique circular tables. The parts to be machined are transferred from one processing station to the other where it is possible to perform numerous operations at the same time, such as drilling, milling, turning, etc. Carrying out the machining of parts simultaneously and not sequentially, as is the case with most processing-centres, results in an enormous increase in the machining efficiency. The design of the machine and the transfer-function visualises Mikrons technological competitive edge in this field. Due to the optimised ergonomics and operating concepts a maximum level of safety, dependability and productivity has been reached.

发布于2019-11-28

设计公司

Process

设计师

Peter Wirz, Walter Eichenberger, Andreas Sickert, Matthias Nitz

设计奖项

德国iF设计奖

iF DESIGN AWARD/iF设计奖

2006 年

颜色

相关推荐