1/10

Can NIVEA’s 3D printed shower gel refill station prototype really reduce plastic packaging waste?

Brands are consciously moving towards eco-friendly practices and the first hurdle every single one of them has to overcome is plastic packaging waste. NIVEA’s parent company is German giant Beiersdorf and they are on a mission to reduce packaging waste by minimizing and closing their material cycles. And for NIVEA that meant launching a shower gel refill station! Now it is a good first step and has its pros but also has some cons. The biggest con is that shower gels itself are not good for the environment and there is no way to know how many bottles actually get rinsed clean before they are recycled – otherwise, it doesn’t work. Shower gels also need a lot of water to be made, and as climate change makes the world hotter/drier, the water crisis is already a big issue in many countries. A solution to that? Bar soaps! NIVEA makes those too, they use less water and can be packaged in recycled paper – that is the real solution but if this refill station reduces some plastic waste and sparks a movement for the brand to take bigger steps, then we are here to see it.

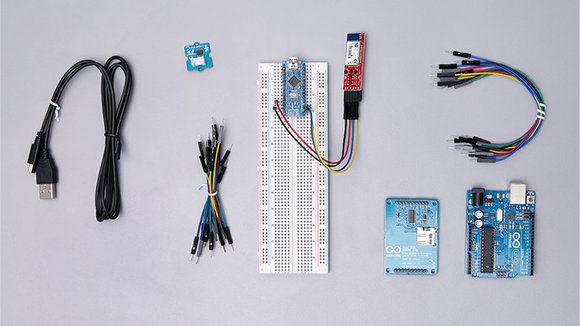

The prototype is going to be tested in select locations where the brand will gather data on how consumers are interacting, feeling, reacting to the concept of reusable bottles. The prototype machine was made with their in-house 3D printers

NIVEA hopes that with this refill station they will make it convenient for consumers to reuse containers and reduce plastic usage. Once they experience that it is easy to make small sustainable lifestyle changes, they will be quicker to adopt it as a habit. The refill station has been carefully designed, developed, and engineered by a cross-functional team within Beiersdorf’s global packaging and R&D functions. Consumers can refill up to three times before sending their bottles to be recycled and get a new one for hygiene reasons – this limitation slows down the plastic consumption problem but without longevity in the solution, it will not end the cycle.

Caroline Zia, Senior Formula Developer at Beiersdorf wanted to make sure that the concept worked for sustainability and for the consumer’s experience. “The formulations need to withstand the additional burden of refilling and we had to carefully choose our products after extensive internal testing. Also, the machine had to be programmed for additional cleaning protocols so that we could guarantee multiple filling loops and still meet our safety and sustainability criteria,’ she explains. The machine’s design had to also account for the retailer’s interior requirements while providing easy user experience. “We decided to use light as visual support to guide the users. Whenever one of the dedicated refill-bottles has been filled or a bar code has been printed, the integrated LED lights give feedback to the consumer,” says Marta Suslow, Concept Designer at Beiersdorf’s packaging department. Other details include formula choice and refill cycles, sophisticated pumps, color-changing lights, a label printer, and a programmed microcontroller.

While this is a good start, personal care brands, especially global giants like NIVEA can step up their game to find real solutions that make it a sustainable choice. You already have the product and the presence, pivot to reducing plastic waste at a larger scale as well as reduce water consumption with one ‘clean’ move – soap.

Designers: Marta Suslow, Caroline Zia, Koushik Sreedhar, Bernhard Felten, Cecile Ratschow of Beiersdorf

发布于2020-11-05

颜色

相关推荐