1/9

These magnetic modular glasses with a hingeless design resolves the most common frame breakage problem!

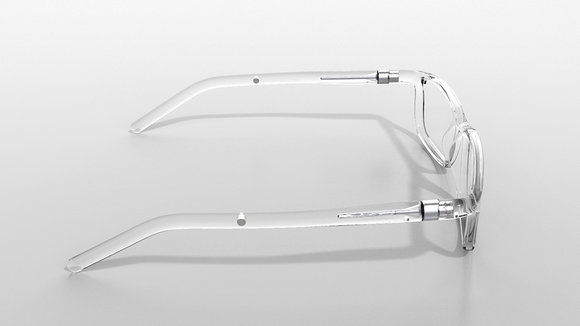

MagLeg is a pair of 3D-printed magnetic eyeglasses that allow for hingeless, unrestricted movement of the temples with an ergonomic design.

If you wear glasses, then you know the struggle of keeping them in one piece. All it takes is one wrong move and your glasses are squashed, scraped, or broken. The temples of glasses are especially notorious for breaking off at the hinges. The temples of glasses are flexible to point, but when they’re over flexed to fit larger head sizes, the hinges snap from too much tension. For designers Marc Sapetti and Arthur Carvalho Vieira, this is all too familiar, so they created MagLeg, a pair of 3D-printed magnetic eyeglasses that allow for hingeless, unrestricted movement of the temples with an ergonomic design.

Small magnets are embedded into the temples and rims of MagLeg to connect all the pieces together and these magnets curve upwards only slightly to ensure an upright fit. Sapetti and Carvalho Vieira set out to design a pair of eyeglasses that stands the test of time and wear, looking toward magnetic joinery to bring them there. Each pair of eyeglasses comes in three parts: the isolated frames and two temple legs. Embedding the tip of each temple with small magnets, they connect to each corner of the rims to form a single pair of glasses.

While MagLeg’s construction is unique and unlike any other pair of glasses on the market, their appearance remains inconspicuous. Magnets replace the hinges of traditional eyeglasses, allowing for unrestricted movement at the temples and rims. Following a thorough research period filled with interviews and trial periods, Sapetti and Carvalho Vieira took a human-centric approach in creating MagLeg. The designers note, “We noticed a gap in the glasses industry. These magnetic glasses were developed to address the lack of lasting glasses that also offer stylish design and human comfort. We used our experience from other segments like backpacks and industry-machines to come up with this innovative solution.”

The frames are produced in high volume following a plastic injection template or a 3D printmaking process that uses nylon material to create the eyewear. The designers followed a thorough period of research with trial runs of their eyeglasses on 3D-printed heads to ensure a comfortable, secure fit. Using these construction processes opens the door to customization work that might call for acute measurement adjustments or color changes. The magnetic and modular makeup of MagLeg also makes for easy and long-lasting maintenance, allowing users to reorder individual parts of their glasses instead of having to order an entirely new pair of frames.

发布于2021-08-17

设计师

Marc Sapetti and Arthur Carvalho Vieira

相关推荐