1/21

This DIY desk chair doubles as a doghouse and bed to get those little puppies off your lap!

Simone Giertz, a self-described maker, robotics enthusiast, and non-engineer, has a dog, Scraps who loves to sit on her lap and a desk chair that could be improved because of it. Dogs especially like sitting on top of you when you’re working on less important matters, like your job. Searching up and down Google’s limits, Giertz noticed time and time again that there weren’t any desk chairs on the market designed for people with small dogs whose preferred seated position was located anywhere on their owner’s body. So, in the trailblazing nature of her YouTube channel, she designed her own.

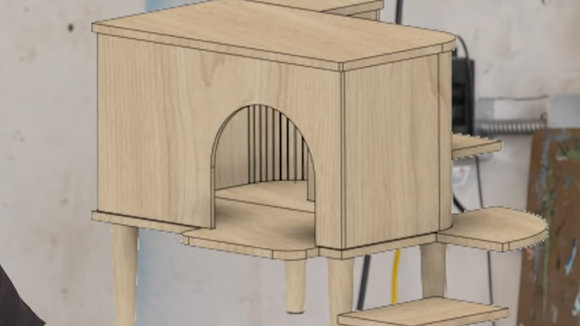

In her uploaded YouTube video, A chair made for needy pets Giertz takes us through the construction of both the chair’s initial prototype and its final form. Using Fusion 360, Giertz created a 3D model of the pet chair. The model features an enclosed crate, the main dog door, footrest, stairs, and roof to also work as Giertz’s seat. Employing CNC milling to construct the chair’s top seat and roof, sidewalls, stairs, and front entryway, Giertz cut vertical ridges along the sidewalls to bend them around the radius of the chair. After mounting the pieces of plywood together to form the prototype’s planned structure, Giertz uses screws to attach them, but the finished prototype saw some improvements.

Giertz turned to CNC milling to construct the chair’s bottom piece, this time formed in two sections to fit onto the CNC bed. On top of the chair’s joined bottom piece, the rest of the CNC-milled pieces of plywood came together. To help Scraps move up and down the chair’s steps with more confidence, Giertz narrowed the distance between the steps and added a railing system to border the chair’s stairs, main seat, and roof.

Increasing the size of the dog house’s main door and solving the trouble that came with bent plywood, Giertz opted for a fuller opening located in the spot where the plywood had to bend around the chair’s radius, leaving less tension in the wood. To see Giertz build the chair from the ground up and paint it a “moldy, vomit color,” as she describes (although I’d like even a moldier seafoam green) – scroll below and be sure to watch the video on Giertz’s YouTube channel!

Using Fusion 360, Giertz created a 3D model.

Using CNC milling, Giertz had her pieces of plywood ready for construction.

To connect the chair’s walls to its base, Giertz relied on peg-and-socket building methods.

Giertz eventually decided on using screws to connect the pieces of the chair together.

To help Scraps feel more comfortable moving up and down the stairs, Giertz thought to add in a railing system.

The final prototype saw improvements for the stairs and built-in railing.

Stepping away from ridge-bent plywood, Giertz increased the size of the chair’s entryway to get rid of some of the tension in the plywood.

Finally, Giertz incorporated a railing for the top of the chair and doghouse roof so that she could comfortably lean back.

The finished product includes the fundamental features from the initial prototype, including stairs and footrest.

To enhance the chair’s overall usability, Giertz integrated pull-out drawers into the stairs.

发布于2021-08-17

设计师

Simone Giertz

相关推荐