1/20

You can now turn your Snapmaker 2.0 into a high-precision 4-axis CNC machine with this new rotary module!

Thousands of Snapmaker users are in for a surprise today as the company unveils yet another module to bring even more functionality to your fabrication-station. Released as a part of Snapmaker’s #StayFoolishKeepMaking campaign to celebrate the ‘Maker’ spirit, the Rotary Module for the Snapmaker 2.0 turns your device into a bonafide 3D printer and rotary CNC machine and laser-engraver. The rotary module unlocks a new dimension in your fabrication process, allowing you to jump from 2.5D CNC machining to incredibly detailed and accurate machined designs that look as good as (if not better than) 3D prints. Fitting perfectly into Snapmaker 2.0’s diverse ecosystem, the rotary module unlocks a new world of functionality, prototyping, and opportunity to the already-versatile machine. The Snapmaker 2.0 was designed to democratize in-house prototyping by simplifying professional-grade tech to make it consumer-friendly (

). With the new rotary module, the user is empowered further, and is given new opportunities to put their ideas to the test.

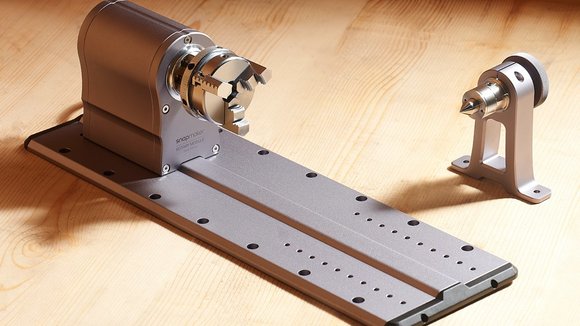

The rotary module belongs to the Snapmaker’s modular ecosystem, integrated seamlessly into the Snapmaker 2.0’s workflow with a snap. It replaces the flat-bed attachment and can work in conjunction with the CNC module to give you a 4-axis CNC machine, the 3D printing module to let you print on curved surfaces, or even the laser-etching/engraving head to let you laser-carve artworks on cylindrical or curved surfaces. The module comes with a swappable 3-jaw chuck that can clamp inwards or outwards, along with a dedicated tailstock that gives you extra stability during precise operation. The module also comes as bundled with Snapmaker Luban, a custom software that offers an intelligent, visualized G-Code generated workflow to help you set up your projects with ease. Calibrating your machine is simple too, with Snapmaker’s Original Assistant (on its screen-module), you will be guided through the relatively easy process.

Like all of Snapmaker 2.0’s components, the rotary module is precisely machined from an anodized aluminum alloy, making it lightweight yet high-performance. The rotary module comes in two sizes for the A350 and A250, and ships in a bundle along with Snapmaker’s Emergency Stop Button which lets you instantly stop a job in the event of an error or an emergency (the Emergency Stop Button is also separately available as a standalone module). Moreover, the rotary module builds on the infinite capabilities of the Snapmaker 2.0 ecosystem, while also promising to be compatible with all future Snapmaker 2.0 modules that the company releases. Yes, you can take our word for it (we’re not pranking!)

Designer: Snapmaker

The Rotary Module adds a 4th axis to your Snapmaker, making it an extremely mighty desktop CNC machining powerhorse, and much more.

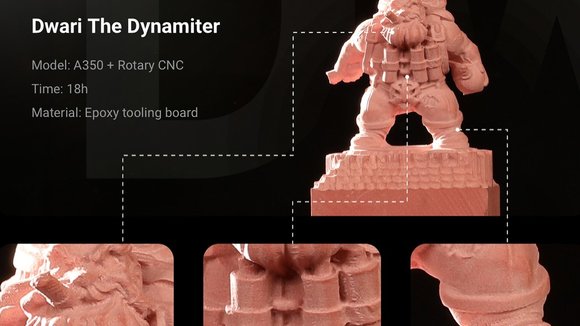

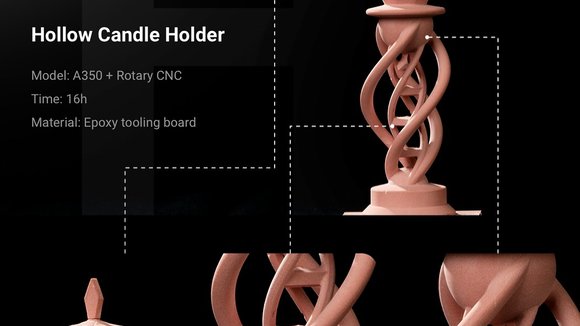

Rotary module excels at making three-dimensional artworks such as desktop miniatures and small-sized sculptures. Without under extrusion, layer shifting, stringing, or supports of FDM or SLA, the rotary module can accomplish a level of detail and craftsmanship that no other 3D printing technologies can.

By adding a 4-axis, the rotary module enables your Snapmaker to rotary CNC carve and laser.

The rotary module supports dozens of materials including wood, tooling boards, plastic, bamboo, leather, fabric, non-transparent acrylics, and more.

Whether it is a brave dwarf king with wavy beards, a beasty orc chiefdom with legendary weapons or a hollow candle holder, the Snapmaker 2.0 Rotary Module can make them all.

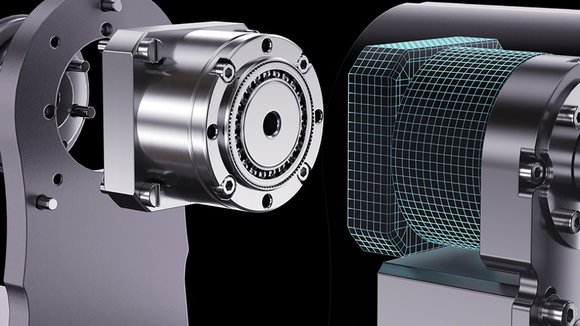

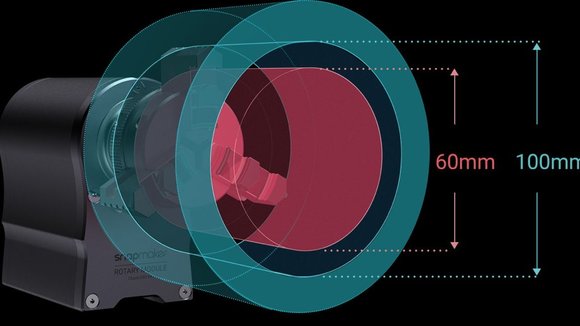

The rotary module uses strain wave gearing and packs a 100:1 speed reducer that converts the power to a lower output speed. This allows the 3-jaw chuck to rotate with a minimum angle of 0.1°. Now, you can make on uneven and irregular surfaces without missing a step.

360° continuous rotation with a maximum angular speed of 45° per second, the rotary module is one fast sculptor. Along with precise control ranging from 0.2, 1, and 5-degree rotation on the touchscreen, you can really see the difference in every motion.

The 3-jaw chuck supports objects with sizes up to 170 length × 68 radius (mm) with the tailstock or 225 length × 68 radius (mm) without the tailstock. You can also use a compatible chuck on the market.

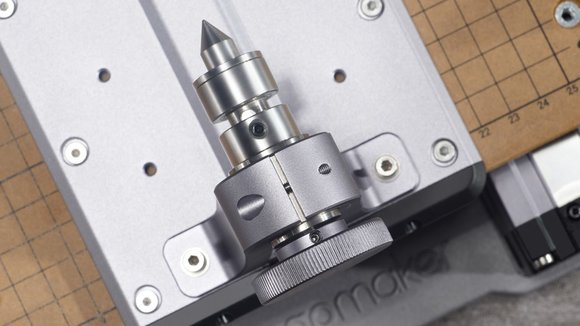

The tailstock center holds objects securely in place.

The base plate has holes on both sides so that you can install the headstock and tailstock at different locations.

Snapmaker Luban is the go-to free CAD and CAM software for your 4-axis projects. You can create your designs from scratch in our bundled software with ease.

Origin Assistant, smoothens your experience and interaction with rotary carving. Presetting CNC bits, setting origins and Z-offsets, and installing materials are made simple. You can also choose Assist Mode for an easier process or Manual Mode for more flexible controls.

The Snapmaker 2.0 Emergency Stop Button can be installed practically anywhere, which means you can easily access the stop button when it matters most. Imagine if you wanted to salvage your art piece or the bit was about to crash into the machine, you pressed the stop button without thinking and further potential harm was prevented.

Check out the #StayFoolishKeepMaking campaign to win a Snapmaker 2.0 Rotary Module Bundle! Share your “FOOLISH” maker stories;

for more information!

发布于2021-08-17

设计师

Snapmaker

相关推荐